Fully Automatic High Speed Rotary Pet Plastic Bottle Feeder Unscrambling Machine Unscrambler

Basic Info.

| Model NO. | LP |

| Origin | Jiangsu, China |

| HS Code | 8422301090 |

| Production Capacity | 100 PCS/Year |

Product Description

Fully Automatic High Speed Rotary PET Plastic bottle Feeder Unscrambling Machine UnscramblerGeneral description

LP series bottle unscrambler is based on advanced foreign technology, according to requirements of beverage filling equipment high speed development, develop a domestic leading level bottle unscramble equipment.

a. Main characteristic

l Main motor reducer adopts torque limit institutions, to prevent failure damaged machine.

l Adopt hang bottle neck air conveyor, to prevent turnover when conveying.

l The bottle unscrambler has stuck bottles detector, if bottle stuck, it will stop automatically and alarm.

l The bottle unscrambler has no bottle detector, which used for sending work signal to the elevator, the elevator will supply bottle automatically.

l Air conveyor has photoelectric switch, which control the start-stop of bottle unscrambler.

l With maintenance door and mold changing door.

l The main electrical component (transducer, PLC, photoelectric switch, relay) use Mitsubishi, Omron, Siemens and other famous brands.

l Pneumatic circuit adopt international brand product.

b. Specification

l Touch screen: Weinview or Pro-face

l Inverter: Mitsubishi

l PLC: Mitsubishi

l Pneumatic cylinder: Festo

l Contactor & switch: Schneider or Siemens

l Photoelectrical switch: Autonics

l Motor: Boneng

c. Technical parameter

Unscrambler

l Model: LP-24

l Number of working positions: 24

l Capacity: 24,000BPH (500ml)

l Pressure of air supply: 0.7MPa

l Air consumption: 2M3/ min

l Applicable bottles: diameter of 50-96mm, height of 165-310mm

l Power of main motor: 4KW

l Dimension: Φ3400×2650 (dia.×H)

l Machine weight: 5000Kg

Elevator

l Model: TP6

l Power of motor: 1.1KW

l Dimension: 6800×800×3400 (L×W×H)

Company Information:

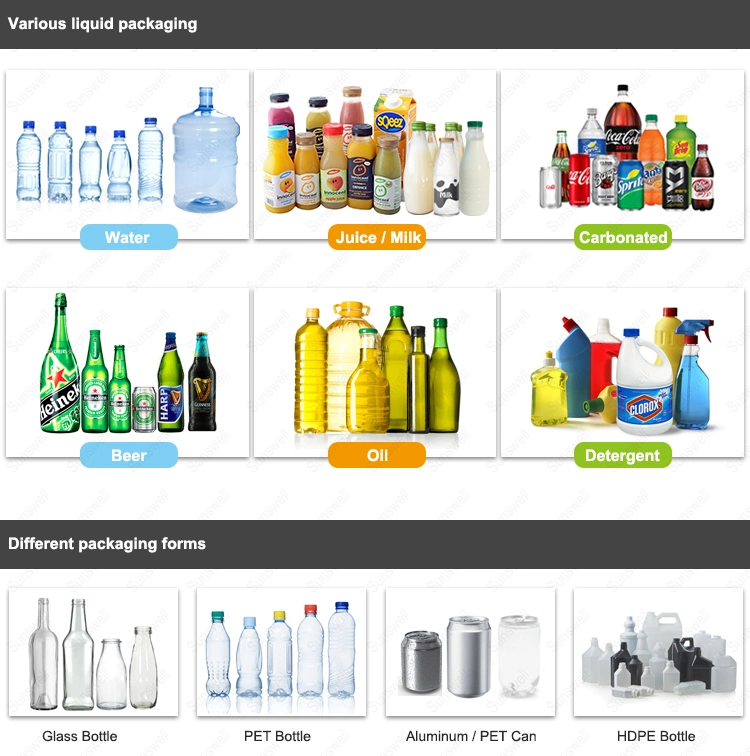

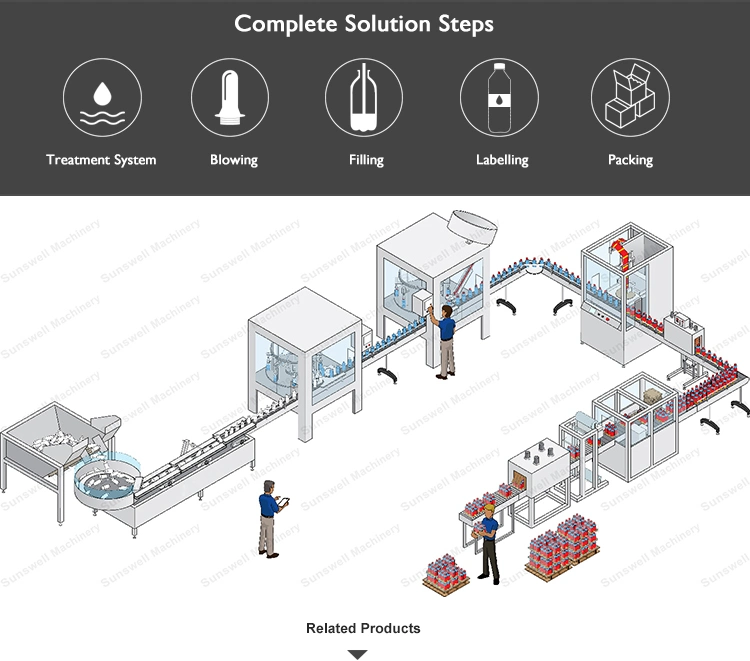

Sunswell leads the market in the field of machinery with advanced technologies in terms of our beverage packaging.We provide a wide range of beverage packaging products. Our machinery has the most comprehensive scope. We enjoy worldwide praise with 10 years of global marketing experience. We have a large number of customers worldwide and we have various end products.Our product range covers all types of machinery for the packaging of liquid, including water, tea, juice, carbonated soft drink, energy drink, alcoholic drink, beer, edible oil, dairy products, etc.We provide good quality and technology from raw material to bottled liquid. We are a good supplier, well known for developing innovative high-end products and new technologies.Our company offers a complete portfolio of support and consulting services, from project engineering to customized solutions and after-sales services. We also provide production optimization, training and advisory services, even end product development. We are looking forward to establishing relationships with you in the near future.

Our Exhibition:

Certificate:Service:Packaging & Shipping:Why Choose Us: 1) Special designed secondary blowing system monitors in time pressure curve of bottle stretch process in each cavity to provide accurate and timely parameters for technical adjustment, which is more convenient for operators to adjust technical parameters. 2) Adopt manipulator transfer technology that cam mechanism has precise control. Catch and send preforms at high speed and the quality is reliable. Taking preform, sending preform, taking bottle and sending bottle match action of opening and closing mould to ensure that the movement process is exact and high efficient. Taking preform, sending preform, taking bottle and ranking bottle are finished automatically by manipulator, avoiding middle pollution.3) The cam mechanism controls exactly opening and closing of mould frame. Special mould locking and pressurizing system and simple and firm mould frame structure can control independently the blowing parameters of each cavity. Good malfunction diagnosis function and special blowing structure ensure the sealing reliability under various pressure. The blowing pressure can be adjusted.4) Stretch rod control exactly preform's axial stretch. The first blow and second blow control preform's vertical stretch. By precise adjustment of the first and second blow, the ideal distribution of bottle wall thickness can be achieved.5) Break conventional design and adopt structure of coaxial rotary bushing with small cubage and light weight. Adopt two deep groove ball bearings to fix two ends to make outside sleeve and core axes concentric, to ensure that the rotary sealing ring is not easy to be damaged. At the same time, increase one water back channel to make the leakage water in Gore circle flows back along pipe, ensuring that the water distributor won't have leakage.Packaging form:

FAQ:

Q1: which city are you in? how can I get to your factory? Are you a trading company or factory?A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packagingmachines. We offer turnkey solutions with more than 10 years experience.Q2: Why is your prices higher than others?A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.Q3: What is your delivery time?A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.Q4: How to install my machines when it arrives? How much the cost?A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If needed. Or you can arrange engineers to study in our factory. You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.Q6: How about the spare parts?A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units to save international courier such as DHL, it is really costly.

Q7: What is your guarantee?A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

Welcome to click "SEND" below for more information!Contact information:

| Name | Flora |

| Address | Zhangjiagang Sunswell Machinery Co.,Ltd. |

| Tel | 0086 512 5850 1665 |

| Fax | 0086 512 5631 0082 |

| Mobile | 0086 187 5282 9782 |

| Web | sunswell.en.made-in-china.com |